Multi-layer solid wood eucalyptus raw materials are assembled layer by layer using environmentally friendly glue, and the surface is covered with multi-layer plywood with melamine veneer, which has the characteristics of high cost performance and strong nail holding force.

It is an artificial board made of wood or wooden poles, crushed logs, with fine wood fibers on both sides and long wood fibers in the middle, which is glued under heat and pressure with adhesive. The panel finish is usually melamine finish, and its cross section presents a honeycomb shape.

The surface of the board substrate has undergone special treatment, adding a layer of PET film with a thickness of 0.35-0.6mm. This board has a delicate texture and soft luster, and is not prone to leaving fingerprints or oil stains.

The raw materials are mainly solid wood materials such as eucalyptus, and the manufacturing process mainly involves drying, sizing, directional paving, and hot pressing of flakes of a certain geometric shape (usually 50-80 mm long, 5-20 mm wide, and 0.45-0.6 mm thick). The formaldehyde emission of OSB is low and it is strong and durable.

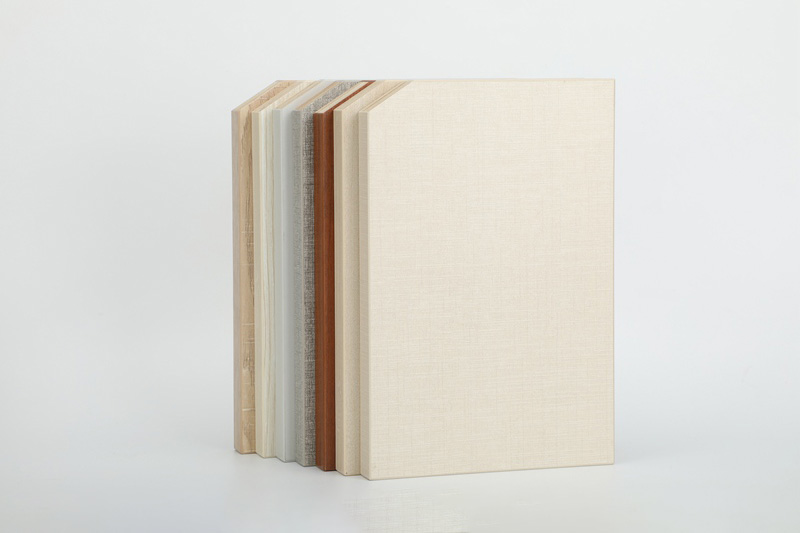

Multi-Layer Plywood Board is a type of plywood, which is made by spinning wood chips into thin veneers or slicing them into thin wood, and then bonding them with adhesive to form three or more layers of plates.

Multi-layer furniture board is a type of plywood, which is made by spinning wood chips into thin veneers or slicing them into thin wood, and then bonding them with adhesive to form three or more layers of plates.

Multi-layer furniture board is a type of plywood, which is made by spinning wood chips into thin veneers or slicing them into thin wood, and then bonding them with adhesive to form three or more layers of plates.

The veneer flame retardant board is attached with a layer of wood grain paper on the surface of the flame retardant board to increase its aesthetics and durability.

Plywood Block Board is a multi-layer board made of a solid wood strip or block core board in the middle and thin wood veneer boards on both sides, which are hot-pressed and glued together. It has both the stability of solid wood and the process characteristics of plywood.

As an innovative man-made board, Zero Voc Plywood has shown broad application prospects in interior decoration, furniture manufacturing, shipbuilding and other fields with its excellent performance and environmental protection characteristics.