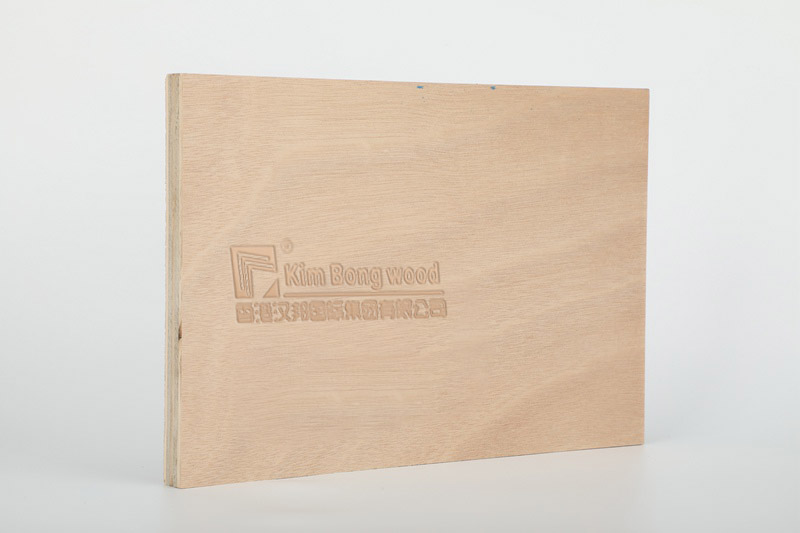

Plywood Block Board

Please click the button below to contact us.

Introduction:Plywood Block Board is a multi-layer board made of a solid wood strip or block core board in the middle and thin wood veneer boards on both sides, which are hot-pressed and glued together. It has both the stability of solid wood and the process characteristics of plywood.

Product Description

plywood Block Board is a multi-layer board made of a solid wood strip or block core board in the middle and thin wood veneer boards on both sides, which are hot-pressed and glued together. It has both the stability of solid wood and the process characteristics of plywood.

plywood Block Board Parameters:

| Item | Parameter |

| Place of Origin | China |

| MOQ | 1000 pc |

| General Specifications | 5mm, 9mm, 12mm, 15mm, 18mm |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Regenerated Wooden Base |

| Transportation | By Sea/By land |

| Quality/Safety Certification | GB/T19001-2016/ISO9001:2015, Hi-tech Enterprise, Attestation of Chinese Environment Mark |

plywood Block Board Features

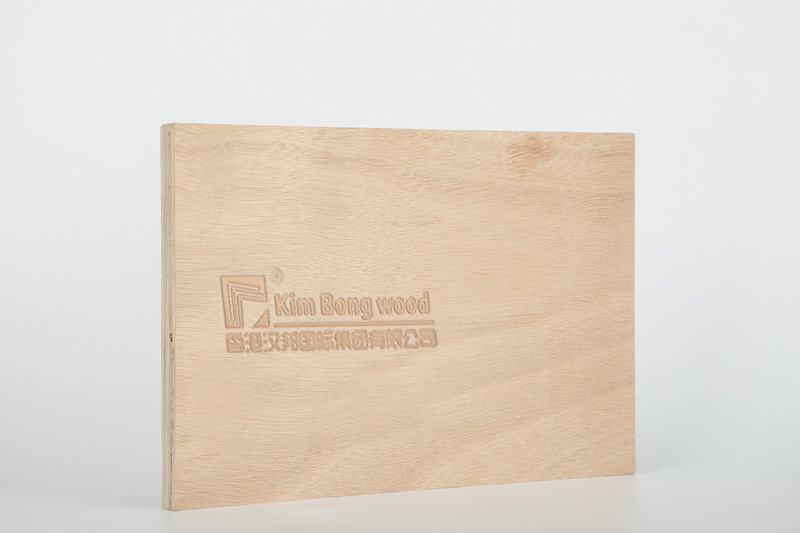

1. Stable structure

The solid wood core board in the middle improves the bending strength and load-bearing capacity of the board, and is not easy to deform or crack.

2. Lightweight

Compared with pure solid wood boards, the overall density is lower, which is convenient for processing and handling.

3. Strong moisture resistance

Due to the gluing process and veneer treatment, it performs better than ordinary solid wood boards in a humid environment.

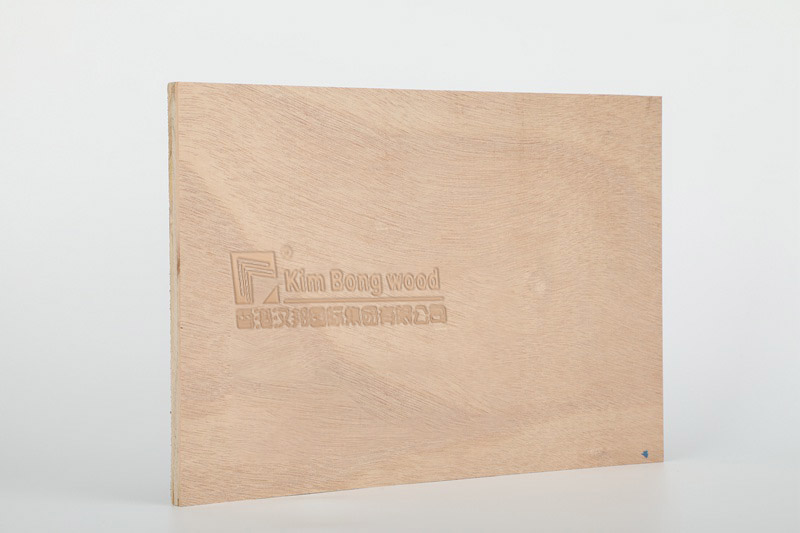

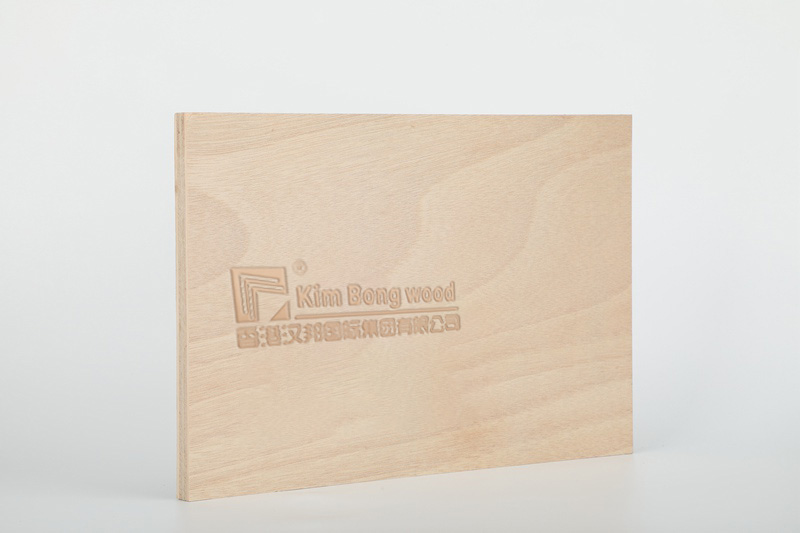

4. Smooth surface

The outer thin wood veneer (such as poplar, birch or imported veneer) makes the surface smooth and suitable for fine processing.

5. Environmental protection

Adhesives that meet industry standards (such as E1 grade) are used, and the formaldehyde emission is controllable.

6. Economical and practical

The cost is lower than that of all solid wood boards, but the performance is similar, and the cost performance is high.

Plywood Block Board More Features

Waterproof plywood Block Board

Waterproof plywood Block Board is another composite artificial board, which is composed of plywood surface layers glued with waterproof glue on both sides of the central wood strip core layer. The board has good waterproof performance, moisture and mildew resistance, good dimensional stability, strong nail holding force, flat board surface, uniform force, and is not easy to deform. It is widely used in interior decoration and furniture making that requires a waterproof and moisture-proof environment, such as kitchen cabinets, bathroom cabinets, bathroom partitions, interior wall panels, cabin decorations, and outdoor awning structures. In addition, it can also be used in construction templates, outdoor terraces and balcony floors, and other engineering projects that have certain requirements for durability and waterproofness. It is a high-performance artificial board with excellent performance and wide application.

Fireproof plywood Block Board

Fireproof plywood Block Board is a man-made board that has been specially processed and added with flame retardants. Its core is made of wood strips and the surface is covered with a flame retardant adhesive layer. It has excellent fireproof and flame retardant properties. The board has a high fire resistance level, burns slowly when exposed to fire, releases low smoke, has good dimensional stability, uniform structure, strong nail holding force, and is not easy to deform or crack. It is widely used in places with high fire safety requirements, such as public entertainment venues, hotels, hospitals, school interior decoration, partitions, ceilings, furniture manufacturing, and

interior decoration of transportation facilities such as airports and subways. It is a safe, reliable and widely used fireproof man-made board.

Mold-proof plywood Block Board

Mold-proof plywood Block Board is a board made of ordinary blockboard with special anti-mold agents and treatment technology, which gives it excellent anti-mold and antibacterial properties. It can effectively inhibit the growth of mold, avoid mold and blackening on the surface, and improve the quality of indoor living environment. In addition, the board is also moisture-proof and stable, has strong dimensional stability, good nail holding performance, and is not easy to deform, which extends the service life of the board. It is widely used in furniture making in humid environments, such as kitchen cabinets, bathroom cabinets, wardrobes, wall decoration, basement decoration, interior decoration projects in coastal areas, and panel laying in hot and humid areas. It is a healthy, environmentally friendly, practical and durable artificial board.

Termite-proof plywood Block Board

Termite-proof plywood Block Board is a man-made board that has anti-termite agent deeply embedded in the core and surface glue layer, and is processed by special process to make the board resistant to termites and other termites. It can effectively prevent damage caused by termites and extend the service life. It also has the excellent properties of flat board surface, uniform structure, high strength, not easy to crack and deform, moisture resistance and insect resistance. It is widely used in interior decoration in humid, termite-prone and underground environments, such as furniture making, interior decoration, wall decoration, floor and cabinets in residences, hotels, villas, schools, hospitals, warehouses, etc. It is a safe, reliable, environmentally friendly and practical new type of insect-proof man-made board.

Plywood Block Board Maintenance method

1. Moisture-proof treatment

Avoid long-term contact with water, and use in the bathroom requires waterproof paint or PVC film.

2. Cleaning method

Wipe with a slightly damp soft cloth. Do not use strong acid and alkali cleaners to avoid damaging the veneer.

3. Avoid exposure to the sun

Long-term direct sunlight can cause the veneer to fade or the core material to crack.

4. Regular inspection

Check whether the edges are debonded and repair them with wood glue in time to prevent expansion.

5. Balanced load-bearing

When used as a layer board, heavy objects should be placed in a dispersed manner to avoid excessive local pressure.

6. Waxing maintenance

Solid wood veneer can be coated with special wood wax oil every six months to maintain gloss and prevent scratches.