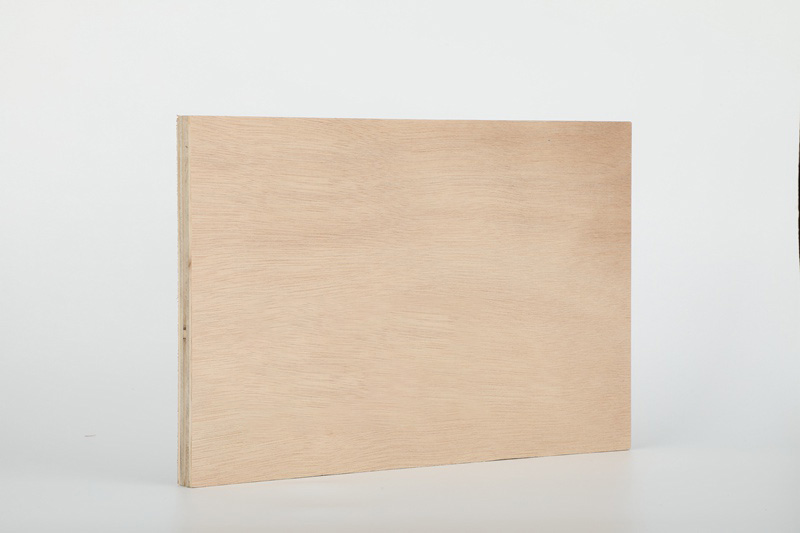

Multi-Layer Plywood Board

Please click the button below to contact us.

Introduction:Multi-Layer Plywood Board is a type of plywood, which is made by spinning wood chips into thin veneers or slicing them into thin wood, and then bonding them with adhesive to form three or more layers of plates.

Product Description

Multi-Layer plywood Board is a type of plywood, which is made by spinning wood chips into thin veneers or slicing them into thin wood, and then bonding them with adhesive to form three or more layers of plates.

The texture direction of each layer of wood chips is usually perpendicular to the texture direction of the adjacent layer, which makes the Multi-Layer Plywood Board have good structural stability and durability. The Multi-Layer Plywood Board has a smooth surface, high longitudinal and transverse strength, good nail holding force, and good water resistance, which improves the durability and stability of the furniture. At the same time, it retains the natural and authentic texture and feel of wood, making the Multi-Layer Plywood Board. It can be used in interior decoration, such as floor lining, ceiling, engineering construction, packaging industry and other fields, and is a versatile board.

Multi-Layer Plywood Board Parameters:

| Item | Parameter |

| Place of Origin | China |

| MOQ | 1000 pc |

| General Specifications | 5mm, 9mm, 12mm, 15mm, 18mm |

| Logo | Accept Customized Logo |

| OEM/ODM | Availalbe |

| Packaging | Regenerated Wooden Base |

| Transportation | By Sea/By land |

| Quality/Safety Certification | GB/T19001-2016/ISO9001:2015, Hi-tech Enterprise, Attestation of Chinese Environment Mark |

Characteristics of Multi-Layer Plywood Board

1. Stable structure, not easy to deform

Multi-Layer Plywood Board is made of multiple layers of wood glued together, and the grain direction of each layer of wood is perpendicular to each other. This cross structure gives the board extremely high stability and anti-deformation ability. Even in an environment with large humidity or temperature changes, it can maintain a good shape.

2. High strength and durability

The superposition of multiple layers makes Multi-Layer Plywood Board have high compressive and bending strength, which is suitable for making load-bearing furniture. Its durability is also far superior to ordinary solid wood boards, and its service life is longer.

3. Excellent environmental performance

High-quality Multi-Layer Plywood Board usually uses environmentally friendly glue and non-toxic paint, which meets international environmental standards, is harmless to the human body, and is suitable for home use.

4. Smooth surface and easy processing

The surface of the board is smooth and flat, suitable for various finishing treatments, such as film, spraying, carving, etc. In addition, Multi-Layer Plywood Board is easy to cut, drill and assemble, and can be flexibly customized according to needs.

5. High cost performance

Compared with solid wood boards, Multi-Layer Plywood Board is more affordable, and has the texture and performance of solid wood, making it a very cost-effective choice.

Application scenarios of Multi-Layer Plywood Board

1. Home furniture

Multi-Layer Plywood Board is widely used in the production of home furniture, such as wardrobes, bookcases, dining tables, bed frames, etc. Its structural stability and aesthetics make it the preferred material for modern home decoration.

2. Commercial space

In commercial spaces such as offices, hotels, and shopping malls, Multi-Layer Plywood Board is often used to make partitions, counters, display racks, etc. Its durability and environmental protection performance can meet the high-intensity use requirements of commercial places.

3. Customized furniture

Because Multi-Layer Plywood Board is easy to process and customize, many customers choose to use it to make personalized furniture to meet unique space layout and aesthetic needs.

4. Outdoor furniture

Specially treated Multi-Layer Plywood Board is also suitable for outdoor furniture production, such as garden chairs, terrace tables, etc., with certain waterproof and weather resistance.

5. Children's furniture

Multi-Layer Plywood Board, with excellent environmental performance, is an ideal choice for children's furniture, ensuring the health and safety of children.

Maintenance methods of Multi-Layer Plywood Board

To extend the service life of Multi-Layer Plywood Board furniture, daily maintenance is essential. Here are some practical maintenance suggestions:

1. Avoid direct sunlight

Long-term exposure to sunlight can cause the surface of the board to fade or crack. Therefore, it is recommended to place the furniture in a dark place or use curtains to block the sunlight.

2. Control indoor humidity

Although Multi-Layer Plywood Board has good moisture resistance, long-term exposure to high humidity may still affect its stability. It is recommended to keep the indoor humidity between 40%-60%, and use a dehumidifier when necessary.

3. Clean the surface regularly

Use a clean soft cloth to wipe the surface of the furniture, and avoid using detergents containing chemical ingredients to avoid damaging the surface coating. For stubborn stains, wipe with a small amount of neutral detergent diluted.

4. Prevent scratches from sharp objects

Try to avoid using sharp objects to directly contact the surface of the furniture to avoid leaving scratches. If scratches occur accidentally, they can be repaired with special furniture repair wax.

5. Wax or oil regularly

For uncoated Multi-layer furniture board furniture, it is recommended to use furniture wax or wood oil for maintenance regularly to enhance its waterproofness and glossiness.

6. Avoid long-term pressure from heavy objects

Although Multi-Layer Plywood Board has a strong load-bearing capacity, long-term placement of heavy objects may still cause deformation. It is recommended to reasonably distribute the load-bearing of furniture to avoid excessive local force.

7. Check the connectors

Regularly check whether the screws, hinges and other connectors of the furniture are loose, and tighten or replace them in time to ensure the stability and safety of the furniture.

More Details about Multi-Layer Plywood Board: